Banyan, a one-stop shop for rig data analytics, event prevention, and predictive maintenance

Banyan

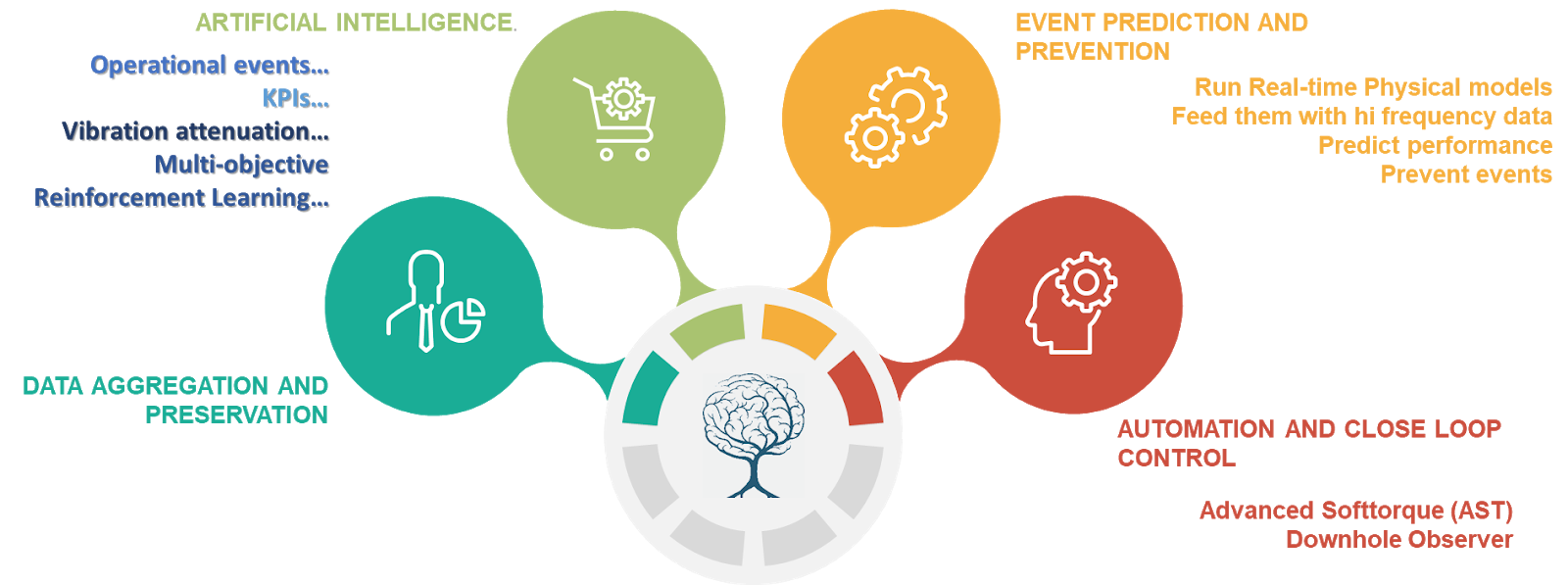

The Banyan data-aggregation-and-automation platform lays the foundation for information-based operations both at the edge, at the rig site, as well as at the corporate level, delivering timely information to key and relevant decision-makers.

In this digital age, Banyan’s success lies in its ability to collect high quality and comprehensive data, and to deliver context for this data, enabling a wide spectrum of advanced functions. This ranges from automation for event-prevention functionality to predictive maintenance, and delivering insights for data-driven efficiency programs to achieve operational excellence.

It starts with high-quality data

Rigs traditionally produce data once every 3–5 seconds. At best, the Electronic Data Recorder (EDR) publishes data at 1 Hz. Events such as drill-string stall, twist-off, and certain aspects of stuck pipes develop and manifest themselves in a matter of seconds. If data is not collected at a high enough sampling rate, then operational events leading up to a drill-string stall or a twist-off cannot be detected.

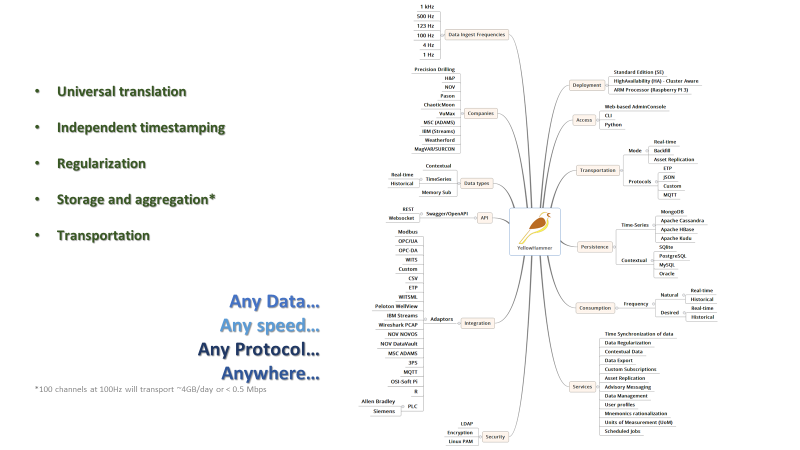

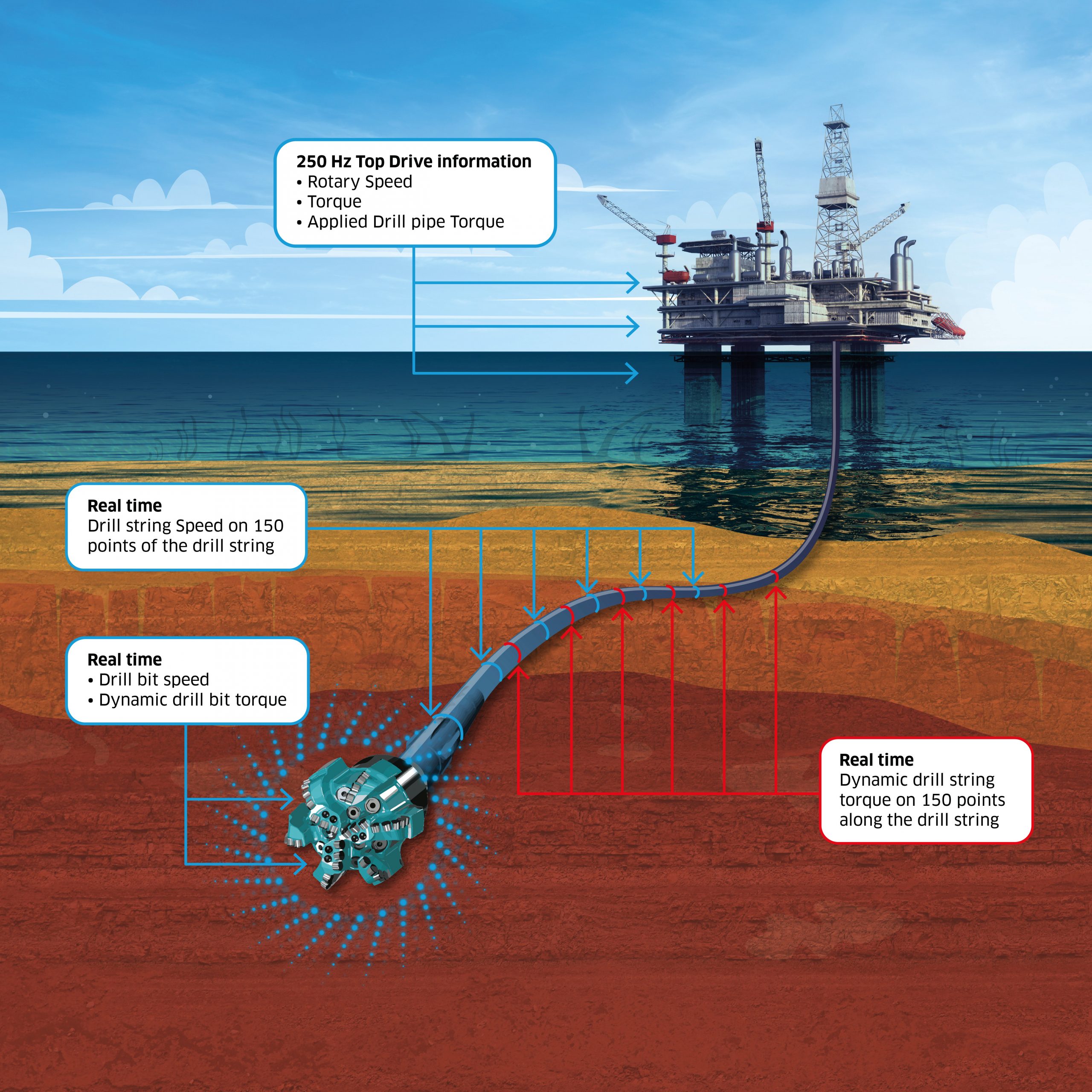

The Banyan platform is a state-of-the-art system that provides data from all sources and all data frequencies for immediate consumption at the edge. Additionally, the platform offers a validated physics-based model that provides information about the dynamic sub-surface behavior of the drill string, both along the drill string and at the bit.

One of the problems in our industry is the diversity of data systems and providers, each with its distinctive protocol. Banyan is a universal translator and a protocol-agnostic data-aggregation system, which can be rolled out across a rig fleet, for a truly rig-manufacturer and rig-operating-system neutral platform.

Context is then needed to interpret the data

In addition to density, what is needed is the context for the aggregated data. Banyan aggregated data is correlated with downhole information delivered by the integrated DigiSub application.

Downhole information is invaluable when combined with surface data for interpreting the behavior of the various rig components. For instance, severe drill-string oscillations exert tremendous stress on drill-string connections, which could potentially cause a twist-off. Banyan allows for the computation and collection of downhole torque and speed data, at a 4-millisecond resolution, without the deployment of expensive downhole sensors.

Additionally, the AI-based recognition of operational events, without human intervention, delivers the context to recognize detrimental events for the drilling operation.

Banyan, when done right, provides the following:

- A one-stop shop for the acquisition and aggregation of data produced via various protocols, of various formats, frequencies (1 Hz, 5 Hz, 20 Hz, 100 Hz, 250 Hz, etc.), and clocks. Synchronized, streamed to whichever real-time user needs it, or stored for historical use.

- Artificial-intelligence-based recognition of operational events, avoiding human intervention when delivering advanced analytics applications.

- Banyan generates model-based downhole information, speed, and torque at the bit and along the drill string, which is available without a downhole sensor.

- Both edge analytics and ROTOC applications not only generate recommendations to the rig personnel in situ but are also useful for on-rig visualization and reporting.

- The ability to securely and efficiently transmit data – as much or as little of the raw and computed channel data as desired, at any desired cadence (1 Hz, 5 Hz, 20 Hz, 100 Hz, 250 Hz, etc.).

- Unique real-time torque and drag application and real-time drill-string behaviour visualization based on the real-time running of drill-string physical models, avoiding the need for expensive sensors downhole.

- The capability to train the Banyan Predictive Maintenance (PdM) module through machine-learning (ML) algorithms.

- The ability to make visible time spent, which was formerly invisible – invisible lost time (ILT).

This information will allow both the operator and the contractor to automate the ILT-reduction initiative and gain immediate benefits as data is collected and processed in situ, as well as in the corporate environment.

Partners worldwide

Local support is important to us, which is why we work with a global network of sales and service partners.

How will Banyan help you to achieve operational excellence?

Let’s discuss it!

Do you want to contact us or one of our partners?

Commercial and technical support is close by.

Read more about Banyan?